Post-Consumer Plastic Recycling: Transforming Waste into Value

Dr. Asangi Gannoruwa - Senior Lecturer , University of Sri Jayewardenepura

Light weight, durability, possession of a wide variety of properties, and being a cheaper material, plastics has become the most popular consumer raw material in the world. Its application varies from packaging, containers, bottles, furniture, and even in healthcare products. However owing to its non-degradability or longer times taken to degrade, it has become one of the most pressing environmental challenges we face. With smart strategies and collective action, we can transform plastic waste into a resource at least up to some extent to save our planet.

According to a report by Monica Dokl and the team in 2024, global plastic use continues to rise at an alarming pace. In the year 2020, consumption was around 464 million tons and, unless things change, it is projected to reach about 884 million tons by 2050. Over the same period, cumulative plastic or the total volume of plastics created and still in circulation, could reach about 4,725 Mt. According to the National action plan on waste plastic management in 2021-2030 published by the Ministry of Environment Sri Lanka, we import virgin plastic raw materials amounts to 300,000 Metric tons per annum. According to the study by Roland Geyer, it was found that as of 2015, approximately 6300 Metric tons of plastic waste had been generated globally, around 9% of which had been recycled, 12% was incinerated, and 79% was accumulated in landfills or the natural environment. Hence, proper strategies to manage plastic waste are mandatory for a sustainable future.

Waste Management and the 3R Concept

The main strategy used for the waste management is the 3R concept, Reduce, Reuse, Recycle. However, due to the nature of solid waste makes the recycling process complex. The diversity of plastic waste streams and the sheer volume make it hard for recycling facilities to keep up. As a result, some recycled plastics end up being low quality or are still sent to landfill. It’s also tough to reduce plastic usage for essential goods without disrupting supply chains or consumer convenience. Economic factors play a big role as producing virgin plastic is often cheaper than recycling. Further, the consumer behaviour is also matters, as many prefer lightweight, convenient plastics over heavier alternatives like glass or metal. Until we shift those preferences, the waste challenge remains. Further, proper waste collection procedures have to be implemented for effective plastic waste management.

Recycling Methods for Plastic Waste

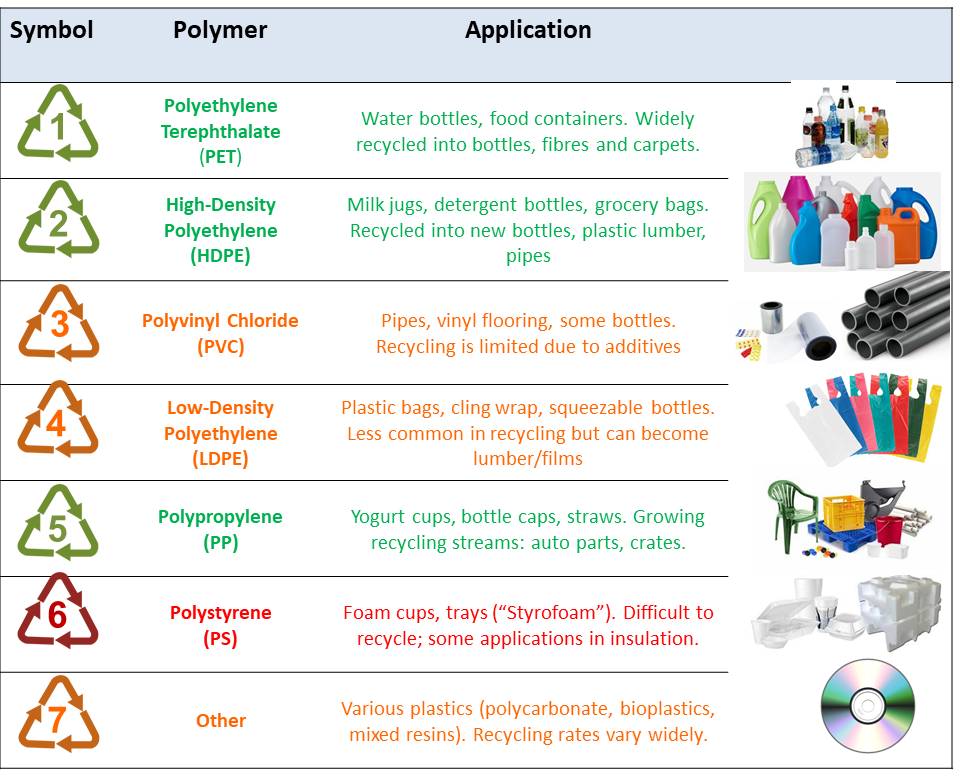

Plastic recycling involves transforming post-consumer or post-industrial plastic waste into secondary materials that can be reintegrated into the production system, either for reuse in the same capacity or for manufacturing new products with comparable or enhanced functionality. This process is central to the circular economy, as it minimizes waste generation while maximizing the utilization of recycled materials. The most commonly used plastics are polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), polystyrene (PS), and polyvinyl chloride (PVC). They are widely found in packaging, construction, automotive, and electronic applications Proper recycling of these materials not only reduces environmental burdens but also contributes to achieving a circular economy associated with plastic production and consumption. Plastic recycling can be categorized into two main types: mechanical and chemical recycling.

Mechanical recycling is a physical process that converts plastic waste into secondary raw materials without significant chemical alteration. The process typically involves sorting, cleaning, shredding, washing, drying, and pelletization, followed by extrusion or molding into new products. This method is cost-effective and widely applied for post-consumer plastic waste originating from municipal, agricultural, livestock, industrial, and commercial sources. A key challenge in mechanical recycling is the deterioration of polymer chains due to thermo-oxidation and shear-induced reactions. Antioxidants, plasticizers, fillers, compatibilizers, and chain extenders are often incorporated to stabilize polymers and restore desired properties.

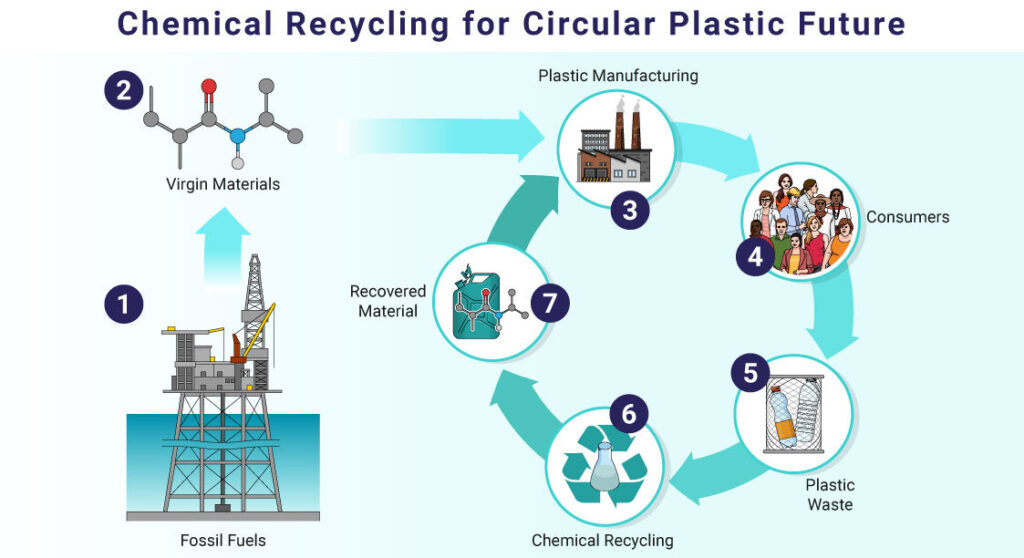

Chemical recycling converts plastic waste into monomers, oligomers, or other raw materials suitable for producing virgin plastics or fuels. Major processes include pyrolysis, hydrocracking, and solvolysis, which allow for depolymerization and recovery of chemical feedstocks. Therefore, chemical recycling can handle mixed or contaminated plastics, offering a pathway to recover value from materials unsuitable for mechanical recycling.

Post-Consumer Recycled Materials

Post-consumer plastics are materials discarded by consumers after use, commonly found in landfills, waterways, and oceans. Examples include plastic bottles, food containers, and packaging materials. When these plastics are collected and recycled, they are called Post-Consumer Recycled (PCR) materials.

PCRs are produced from everyday recyclable items such as aluminum, cardboard, and plastics. Waste plastic materials are collected through recycling programs then they are sorted, cleaned, and processed into bales. The bales are then melted or ground into pellets, which can be molded into new plastic products ranging from packaging materials to textiles and household goods.

Here’s how it works:

- Plastics are collected from homes, businesses, recycling stations.

- They are sorted by type (see “How to Identify Plastics” below).

- Contaminants (food scraps, labels) are removed.

- The clean plastics are shredded/granulated into small pieces.

- Granules are melted and extruded into new pellets, which are then molded into new products (e.g., bottles, packaging, fibre).

How to Identify Plastics

Recycling works best when plastics are correctly sorted. The triangular recycling symbol with a number (1 to 7) helps identify the resin type:

PCR, Recyclable, and Compostable Plastics

It is important to know the differences between the PCR, Recyclable plastics and the compostable plastic for efficient waste management. Recyclable plastics are designed to be processed and reused, but their success depends heavily on consumer behavior such as correct sorting, disposal into the right bin, and access to proper recycling infrastructure. Without these factors, even recyclable materials can end up in landfills. PCR plastics, on the other hand, are made from materials that have already completed one life cycle. The polymer quality often degrades after the first recycling process making further recycling more difficult. PCR offers a powerful way for brands to reduce reliance on virgin plastic and achieve sustainability targets without depending entirely on consumer recycling habits. In Sri Lanka, companies such as Eco Spindles (Pvt) Ltd and Phoenix Industries Ltd are leading efforts to produce goods made from PCR materials. Compostable plastics differ significantly from the previous two types. These materials are designed to decompose into substances like carbon dioxide, water, and biomass. The degradation rates are comparable to natural materials such as paper or cellulose. However, industrial composting facilities required for this process remain limited in many regions. Additionally, both recyclable and compostable plastics can generate micro-plastics during degradation, posing ongoing environmental challenges.

The Benefits of PCR Plastics

Post-Consumer Recycled (PCR) plastics offer far-reaching benefits for the environment, consumers, and businesses alike. Environmentally, using PCR significantly reduces the demand for virgin plastics, conserving non-renewable fossil fuels, lowering carbon emissions, and reducing the energy required for production of raw materials. Further, by recycling plastics, solid waste going to landfills can be decreased and hence help to address the growing issue of micro-plastics in oceans and waterways. Modern PCR material processing technology has reached to a state to match the strength, durability, barrier performance, and reliability of virgin plastics, offering the same protection against light, oxygen, and moisture. From a business perspective, integrating PCR materials enhances brand value, resonates with eco-conscious consumers, and improves customer retention, as studies show a majority are willing to pay more for sustainable products. Furthermore, using PCR supports long-term sustainability by promoting a circular economy and helping companies comply with regulatory standards on recycled content in packaging. For the everyday consumer, PCR plastics make sustainable choices effortless, as recycled content is built directly into the product, requiring minimal action after purchase. In Sri Lanka, where green consumerism is on the rise, adopting PCR packaging offers brands a tangible way to differentiate themselves while contributing to a more sustainable future.

What You Can Do

You, the consumer, have a key role to play:

- Sort your plastics by type (check the recycling number).

- Rinse out plastics to remove food residues or liquids. Clean materials help recycling.

- Reduce single-use plastics: opt for reusable bottles, bags, containers.

- Choose products from companies using recycled packaging or sustainable materials.

- Spread awareness: talk with family, friends, and neighbours about how to recycle well and why it matters.

Plastic doesn’t have to be a throw-away problem. With the right mix of policy, industry strategy and everyday action, we can shift it from waste into value. By embracing the 3Rs, supporting PCR packaging, and staying informed, each one of us can help close the loop on plastic. The future is clean, circular and it begins with the choices we make today.

References

- Beghetto V., Gatto V., Samiolo R., Cristina Scolaro C., Brahimi S., Facchin M, Visco A. (2023) “Plastics today: Key challenges and EU strategies towards carbon neutrality: A review”. Environmental Pollution, 334: 122102.

- Cecon V.S., Da Silva P.F., Curtzwiler G.W., Vorst, K.L. (2021) “The challenges in recycling post-consumer polyolefins for food contact applications: A review”. Resources, Conservation and Recycling, 167: PP.

- Dokl M., Copot A., Krajnc D., Fan Y.V., Vujanović A., Aviso K.B., Tan R.R., Z. Kravanja Z. and Čuček L., (2024) “Global projections of plastic use, end-of-life fate and potential changes in consumption, reduction, recycling and replacement with bioplastics to 2050’. Sustainable Production and Consumption, 51;pp. 498-518.

- Geyer R., Jambeck J.R. and Law K.L. (2017) “Production, use, and fate of all plastics ever made”. Science Advances, 3(7):1700782.

- Ministry of Environment Sri Lanka, (2021) National action plan on waste plastic management 2021-2030, Available at https://ccet.jp/sites/default/files/2021-08/srilanka_report_web_fin_pw.pdf .

- Pilapitiya P.G.C.N.T.,and Ratnayake A.S. (2024) “The world of plastic waste: A review” Cleaner Materials, 11:100220.

- Ragaert K., Delva L., Geem K.V.(2017) “Mechanical and chemical recycling of solid plastic waste”. Waste Management, 69: pp. 24-58.

- Schyns Z.O G. and Shaver M.P. (2021) “Mechanical Recycling of Packaging Plastics: A Review”. Macromolecular rapid communications, 42(3): 2000415.

- Schulze-Netzer C. (2024)” Gasification for material recycling—A solution to the plastic flood?”. Canadian Journal of Chemical Engineering, 102(9): 2966-2979.

- Vollmer I. , Jenks M.J.F., Roelands M.C.P., White R.J., van Harmelen T.V., de Wild P., van der Laan G.P., Meirer F., Keurentjes J.T.F., Weckhuysen B.M.(2020) “Beyond Mechanical Recycling: Giving New Life to Plastic Waste”. Angewandte Chemie, 59(36): pp. 15402-15423.

University of Sri Jayewardenepura