Tiny Science, Big Impact: How Nano-Encapsulation is Transforming Dairy Foods

The word “nano” has become increasingly common in modern science and technology-based research and developments. It refers to structures and materials measured on the nanoscale, typically between 1 and 100 nanometers (nm), where their properties can differ greatly from those of larger particles (Teulon et al., 2018). The rapid development of nanotechnology has made it an important field with diverse applications across food and non-food sectors, especially for improving product quality and functionality. In the food industry, nanotechnology is increasingly utilized to improve the stability and bioavailability of bioactive compounds, enhance food packaging systems, and extend product shelf life. In non-food sectors, nanotechnology is extensively applied in pharmaceuticals, cosmetics, agriculture, and biomedical fields, particularly for targeted delivery systems and enhanced functional performance.

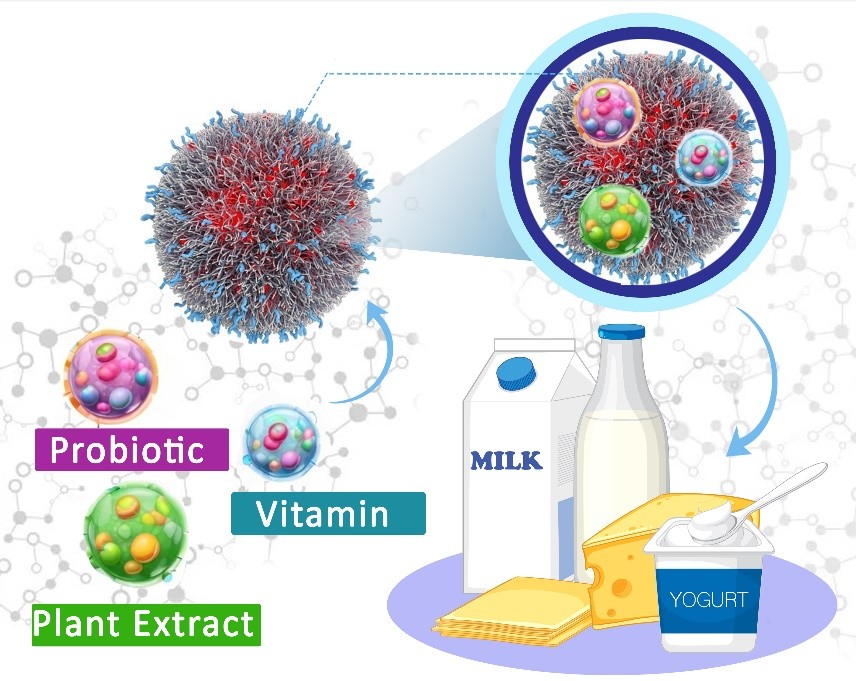

Among the various food applications of nanotechnology, nano-encapsulation is a technique in which tiny particles or carriers are used to surround or “encapsulate” active ingredients such as vitamins, antioxidants, probiotics, or plant extracts (Zhang et al., 2022). Nano-encapsulation is a method used to protect beneficial compounds by keeping them stable and preventing damage during processing. This approach involves incorporating bioactive compounds into nanoscale carrier systems that protect their nutritional value until they are consumed. These nano-carriers are typically formed from food-grade materials such as proteins, lipids, or polysaccharides, which function as protective barriers around the encapsulated compounds. For example, casein, a milk protein, and chitosan, a natural biopolymer, are widely employed to develop nano-carriers suitable for food applications (Maqsood et al., 2025).

Nano-encapsulation is opening exciting new possibilities in the food industry. In beverages, it helps disperse vitamins and antioxidants evenly, preventing their settling and maintaining clear, stable drinks (Kumari et al., 2025). In bakery products, nano-encapsulated omega-3 fatty acids or plant extracts can be incorporated without altering taste (Sonmezler et al., 2025). In meat and fish products, nano-carriers can deliver natural preservatives that extend shelf life and maintain the products freshness (Hanif et al., 2025).

While nano-encapsulation offers benefits for diverse types of food, it is particularly important for functional dairy matrices such as yogurt, butter, cheese, and curd. Dairy systems exhibit unique physical and biological characteristics, including protein–lipid interactions, fat globule structure, and microbial activity, which can influence the behavior of added bioactive compounds. In this context, nano-encapsulation provides several key advantages, including improved stability of bioactive compounds, enhanced bioavailability, controlled release during digestion, preservation of sensory quality, and increased probiotic viability (Bhtoya et al., 2025).

One significant benefit of nano-encapsulation is enhanced stability of bioactive compounds. Encapsulation protects sensitive ingredients such as vitamins, antioxidants, probiotics, and plant extracts from degradation caused by processing and storage conditions, including pH fluctuations, oxygen exposure, and light (Rahim et al., 2025).

Another important advantage is improved bioavailability. Nano-encapsulation helps ensure that bioactive compounds remain intact within the complex protein–fat matrix of dairy products, thereby enhancing their absorption and utilization in the human body after consumption (Ruengdech et al., 2025). Controlled release of bioactive compounds during digestion is also a significant benefit of nano-encapsulation. Functional dairy foods serve as ideal carriers for probiotics and other bioactive compounds, and nano-encapsulation enables these substances to be released gradually within the digestive system (Al-subhi, 2025). This controlled release promotes better long-lasting physiological benefits. Furthermore, natural milk components such as casein and whey proteins are highly compatible with nanoparticles, making dairy an especially suitable medium for encapsulation compared to other food matrices like bakery or meat products (Robles-García et al., 2025).

In addition, nano-encapsulation helps preserve the sensory qualities of functional dairy foods. By masking undesirable flavors and preventing textural changes caused by certain bioactive ingredients, it maintains the taste, aroma, and mouthfeel expected by consumers (Azarashkan et al., 2022).

Moreover, nano-encapsulation enhances the viability of probiotic bacteria in fermented dairy products by forming a protective barrier that shields the cells from environmental stresses during processing, storage, and gastrointestinal transit, thereby strengthening their health benefits (Centurion et al., 2021).

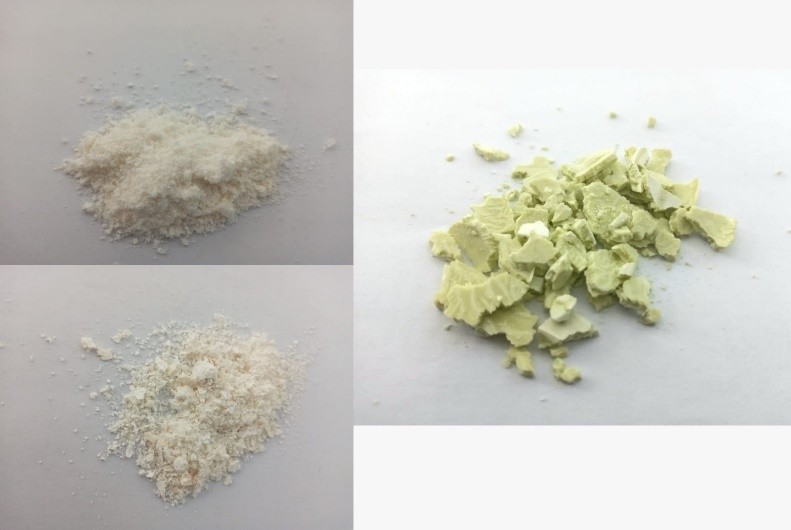

Figure 1. Whey protein–based nano-encapsulated materials incorporating different phytochemical compounds

Figure 1 shows that the research activities conducted at the Department of Biosystems Technology, Faculty of Technology, University of Sri Jayewardenepura, involve a team of food scientists actively studying nano-encapsulation techniques, such as whey protein-based nano-delivery systems, to enhance the stability and delivery of plant-derived compounds in dairy matrices. The research focuses on incorporating nano-encapsulated herbal extracts into functional dairy products, to retain their bioactive properties during fermentation and refrigerated storage.

In addition to laboratory work, the faculty is conducting a nationwide consumer survey to assess Sri Lankans’ perceptions of nanotechnology in functional dairy foods. Early responses indicate that many people are unfamiliar with the concept of nanotechnology; however, they are curious and open to learning more when they understand that it can involve safe, natural, food-grade materials rather than synthetic or harmful substances.

A key question affecting the application of nano-encapsulation in food systems is whether nano-encapsulated foods are safe for human consumption. The answer is yes, when developed responsibly. Nano-encapsulation in the food industry uses food-grade, biodegradable materials that meet international safety standards. Regulatory bodies such as the European Food Safety Authority (EFSA) and the U.S. Food and Drug Administration (FDA) have clear guidelines for evaluating the safety of nano-ingredients (Syed and Krishnamurthi, 2025). Sri Lankan researchers also ensure that the materials used, such as milk proteins and natural polysaccharides, are non-toxic and compatible with human digestion. Ongoing studies are focused on understanding how these nano-particles behave in the human body and on designing delivery systems that are both effective and completely safe (Yildiz et al., 2025).

Finally, food nanotechnology is a science for better nutrition, not science fiction. Nano-encapsulation helps protect and deliver valuable nutrients in functional dairy foods, making products like such as yogurt and butter healthier and safer.

Keywords: Nano-encapsulation, nano-carriers, functional dairy foods, bioavailability, stability

References

Al-subhi, F.M.M., 2025. Development, characterization, and prolonged shelf life of functional yogurt enriched with nanoencapsulated yellow Capsicum Annuum extract using whey protein. Applied Food Research 5, 100758. https://doi.org/10.1016/j.afres.2025.100758

Azarashkan, Z., Motamedzadegan, A., Ghorbani‐HasanSaraei, A., Biparva, P., Rahaiee, S., 2022. Investigation of the physicochemical, antioxidant, rheological, and sensory properties of ricotta cheese enriched with free and nano‐encapsulated broccoli sprout extract. Food Science & Nutrition 10, 4059–4072. https://doi.org/10.1002/fsn3.3001

Bhtoya, R., Pradhan, G., Kumar, S., Dobhal, A., 2025. Advanced fortification techniques in dairy products: enhancement of nutritional value through encapsulation. Nutrire 50, 22. https://doi.org/10.1186/s41110-025-00325-7

Centurion, F., Basit, A.W., Liu, J., Gaisford, S., Rahim, Md.A., Kalantar-Zadeh, K., 2021. Nanoencapsulation for Probiotic Delivery. ACS Nano 15, 18653–18660. https://doi.org/10.1021/acsnano.1c09951

Hanif, H., Arshad, M.S., Khalid, W., Madilo, F.K., Khalid, M.Z., Talah, A., Siddiqa, A., Luqman, A., Alharbi, S.A., Aljawdah, H.M., 2025. Evaluation of Nano‐Encapsulation of Sweet Lime Peel Extract Through Its Application on Irradiated Chicken Meat Patties. Food Science & Nutrition 13, e70124. https://doi.org/10.1002/fsn3.70124

Kumari, S., Debbarma, R., Hussain, S., 2025. Encapsulation strategies for enhancing the stability and shelf life of citrus bioactive compounds. Eur Food Res Technol 251, 3465–3487. https://doi.org/10.1007/s00217-025-04868-x

Maqsood, S., Dasgupta, P., Khalid, W., 2025. Optimizing Protein Absorption with Nano-Encapsulation, in: Chatterjee, A., Sarkar, T., Smaoui, S. (Eds.), Nanofuel: The Future of Sports Nutrition, Smart Nanomaterials Technology. Springer Nature Singapore, Singapore, pp. 133–159. https://doi.org/10.1007/978-981-96-5471-0_5

Rahim, M.A., Zahran, H.A., Jaffar, H.M., Ambreen, S., Ramadan, M.F., Al‐Asmari, F., Castro‐Muñoz, R., Zongo, E., 2025. Liposomal Encapsulation in Food Systems: A Review of Formulation, Processing, and Applications. Food Science & Nutrition 13, e70587. https://doi.org/10.1002/fsn3.70587

Regulatory principles on food nanoparticles legislated by Asian and Oceanian countries, 2021. , in: Safety and Regulatory Issues of Nanoencapsulated Food Ingredients. Academic Press, pp. 201–238. https://doi.org/10.1016/B978-0-12-815725-1.00006-9

Robles-García, M.Á., Del-Toro-Sánchez, C.L., Limón-Vargas, G., Gutiérrez-Lomelí, M., Avila-Novoa, M.G., Villalpando-Vargas, F.V., Vega-Ruiz, B., Bernal-Mercado, A.T., Iturralde-García, R.D., Gómez-Guzman, A.I.P., Ramírez-Briones, E., López-Berrellez, R.G., González-Vega, R.I., 2025. Development of Fucoxanthin-Enriched Yogurt Using Nanoliposomal Carriers: A Strategy for Functional Dairy Products with Antioxidant and Erythroprotective Benefits. Molecules 30, 1854. https://doi.org/10.3390/molecules30081854

Ruengdech, A., Mishra, D.K., Siripatrawan, U., 2025. Multifaceted roles of foam-mat freeze-dried catechins nanoencapsulation to enhance catechins stability and bioaccessibility, and quality of green tea catechins-fortified milk. Food Chemistry: X 27, 102391. https://doi.org/10.1016/j.fochx.2025.102391

Sonmezler, D., Yazıcıoğlu, N., Sumnu, G., Sahin, S., 2025. Encapsulation of Olive Leaf Extract by Double Emulsion Method for Enriched Bakery Products: Enhancing Stability and Functionality. Food Bioprocess Technol 18, 3356–3374. https://doi.org/10.1007/s11947-024-03671-y

Syed, N., Krishnamurthi, V., 2025. From Nano to Nutrition: Advancing Food Science through Nanotechnology. Translational Food Sciences vxaf018. https://doi.org/10.1093/trfood/vxaf018

Teulon, J.-M., Godon, C., Chantalat, L., Moriscot, C., Cambedouzou, J., Odorico, M., Ravaux, J., Podor, R., Gerdil, A., Habert, A., Herlin-Boime, N., Chen, S., Pellequer, J.-L., 2018. On the Operational Aspects of Measuring Nanoparticle Sizes. Nanomaterials 9, 18. https://doi.org/10.3390/nano9010018

Yildiz, E., Sumnu, G., Khwaldia, K., Rathod, N., Centobelli, P., Kulawik, P., Kaddour, A.A., Dapcevic‐Hadnadev, T., Ozogul, F., 2025. Recent Developments Towards Sustainable Solutions in Electrospun Active Packaging Systems for Various Foods. Comp Rev Food Sci Food Safe 24, e70280. https://doi.org/10.1111/1541-4337.70280

Zhang, Z., Li, X., Sang, S., McClements, D.J., Chen, L., Long, J., Jiao, A., Jin, Z., Qiu, C., 2022. Polyphenols as Plant-Based Nutraceuticals: Health Effects, Encapsulation, Nano-Delivery, and Application. Foods 11, 2189. https://doi.org/10.3390/foods11152189

Authors:

Ms. P.R. Hansani K. Kumari

Research Assistant,

Department of Biosystems Technology,

Faculty of Technology,

University of Sri Jayewardenepura.

Dr. A.M.A.U. Alahakoon

Senior Lecturer,

Department of Biosystems Technology,

Faculty of Technology,

University of Sri Jayewardenepura.

Dr. Niluni M. Wijesundara

Senior Lecturer,

Department of Food Science and Technology,

Faculty of Animal Science and Export Agriculture,

Uva Wellassa University of Sri Lanka

Dr. Rumesh Liyanage

Senior Lecturer,

Department of Biosystems Technology,

Faculty of Technology,

University of Sri Jayewardenepura

Prof. Ranil Coorey

School of Molecular and Life Sciences,

Curtin University.